In manufacturing plants for precision machining, resin molding, and other industries, stable operation of production lines and equipment such as production machines is essential for ensuring product quality. This stability requires chilled water at temperatures close to room temperature (15-25°C).

In recent years, some regions have experienced water shortages during summer, leading to mandatory reductions in factory operating hours. Increased use of groundwater has also resulted in issues such as land subsidence and saltwater intrusion, prompting regulations on water extraction through laws and ordinances. Furthermore, as sewage facilities have been upgraded, water usage fees have been imposed, making it impractical to dispose of water as in the past.

Our Chilled Tower integrates originally designed closed-loop cooling towers and chillers, offering energy-efficient and environmentally friendly solutions. Their energy efficiency contributes to reducing carbon dioxide emissions as well.

Features of a chilled tower

Cost Savings on electricity

We use R407C refrigerant and scroll compressors.

Compared to conventional chiller cooling systems, our system can reduce electricity costs by approximately 60-90% and decrease power consumption by about 30-60%.

Automatically operation throughout the year

Our chilled tower supplies chilled water at a stable temperature to the machines through automatic operation all year round by utilizing inverter control for the fans and controlling the number of compressors.

Compact installation space

Since it integrates the cooling tower and chiller into a single unit, it takes up approximately half the space compared to installing a cooling tower and chiller separately. Additionally, as the chilled tower is designed for outdoor installation, there is no need for a mechanical room.

Easy to install and instrument

Due to its integrated design, it significantly reduces the time required for design and on-site construction. Since the chilled tower includes a built-in control panel, instrumentation work is minimized, requiring only remote control wiring for start/stop and alarm signals from external sources.

Supply clean chilled water

With its internal sealed piping system, the water does not get contaminated within the equipment, resulting in fewer issues caused by water impurities.

Handle large temperature differences at once

With its two-stage cooling system involving both the chiller and the cooling tower, the chilled tower can operate with a larger temperature difference (10-15°C) compared to conventional chillers. This reduces the volume of circulating water and lowers the power required for transportation.

Main applications

Cooling for Production Equipment(Production and Research Facilities)

| Semiconductor Manufacturing, Precision Machinery, and Machine Manufacturing |

Vacuum Deposition Equipment, Sputtering, Diffusion Furnace, Reaction Furnace, Oxidation Furnace |

| High-Frequency Induction Furnace, Vacuum Induction Furnace, Epitaxial Furnace |

| plastic molding machines and molds |

| Etching, Stepper |

| Cutting oil |

| Vehicle |

Aluminum Die Casting Mold |

| Rubber or Paint Mixing Roll |

| Sheet Forming |

| Plastic Molding |

| Laser Processing Machine |

| Vacuum Plating |

| Printing |

Printing Machine Roll |

| Beverages, food products, pharmaceuticlas |

Beverages, food products, pharmaceuticlas Retort Cans |

| UHT |

| Pasteurizers |

| Cooling of bread, noodles |

| Flour drying radiators |

| Manufacturing of soy sauce, miso, etc. |

| Water distilling equipment |

| Chilling of bean jam |

| Flour milling rollers |

| Pharmaceutical Manufacturing Equipment |

| Research organizations, research institutes |

Laser oscillators, Electron microscopes, Diverse testing equipment |

| Air conditioning |

Data center |

| Clean rooms |

| Factory air conditions |

| Machinery room air conditioning |

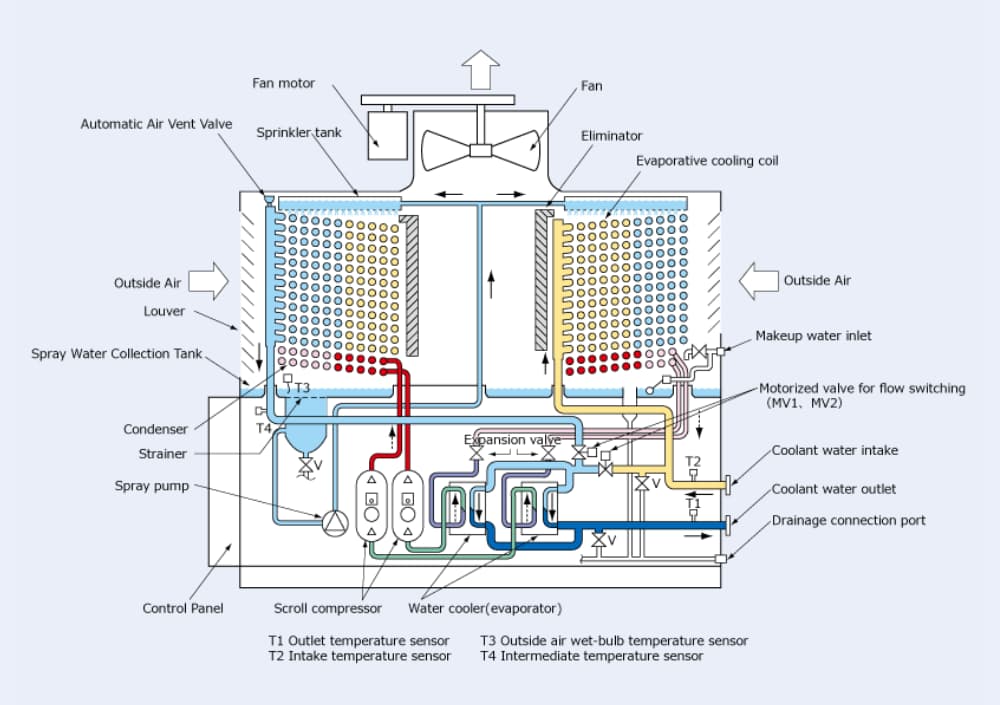

Structural Diagram

The chilled tower is equipped with a sealed cooling coil at the top and multiple evaporative condensing chillers at the bottom. Chilled water entering the chilled tower undergoes maximum cooling in the upper cooling coil section, utilizing a fan-driven airflow and water sprayed for evaporative cooling (primary cooling). The primarily cooled water is then directed to the chiller units located at the bottom of the chilled tower. Here, it is further cooled to the set temperature through heat exchange with low-temperature refrigerant in the water cooler (secondary cooling).

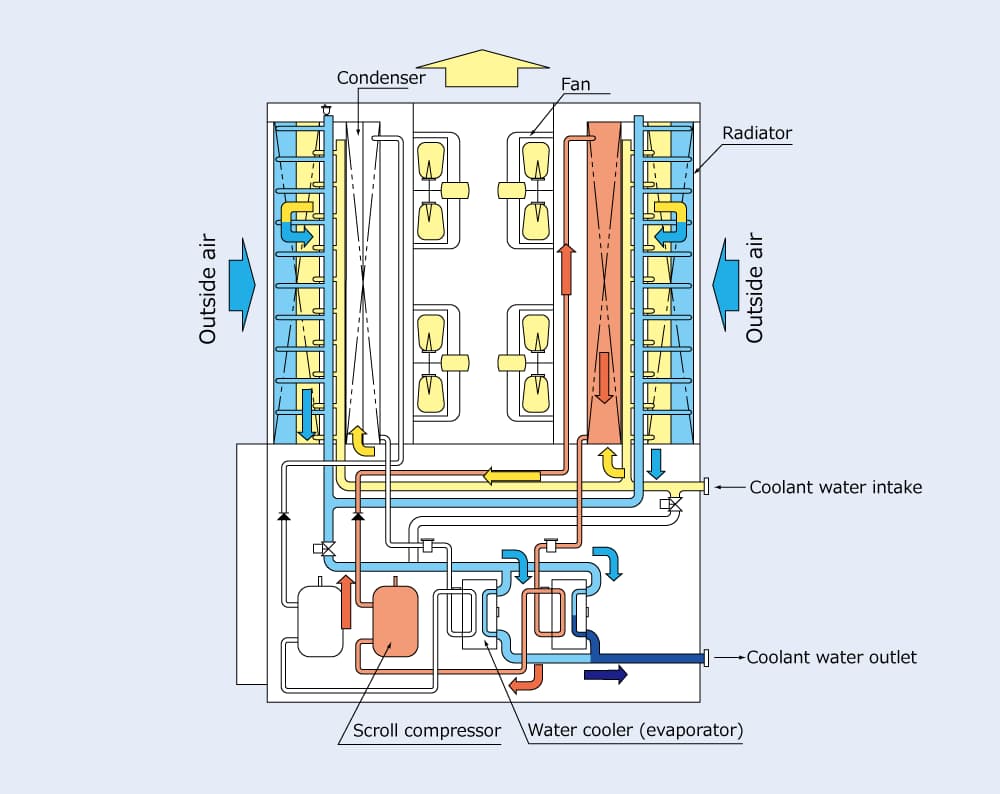

W-Series(Water Cooling Type)

A-Series(Air Cooling Type)